|

The composition of Spirulina shows clearly that it is a

high protein content food with

important

amounts of vitamins, minerals,

and essential

non-saturated fatty acids but

low in calories.

Traditionally it has been eaten

in combination

with cereals, thus making it

an appropriate

food for treating protein-energy

malnutrition

.

If Spirulina is not to be eaten

immediately

at the production site, it should

be dried to a residual humidity content of 7% or less.

|

.

Earthrise Spray-dryier

|

|

Once dried and kept from oxidation and sunlight,

the product can be kept for long periods,

enabling stockage and distribution.

The equipment used for spray drying is costly and it requires major amounts (around

1 KWh per kilo of dried product)

of energy

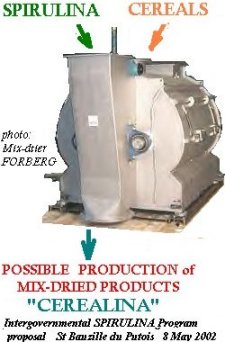

to operate. We find that the

filter cake

instead of going through the

spray drying

process can be dried simply by

being mixed

with dry precooked cereal flour

such as wheat,

maize, millet, rice, oats, barley,

etc..

ln a properly designed mixer

the dry flour

pumps the water from the algae

cake within

about 5 seconds, leaving a perfectly

blended

mixture wïth only about 5 to

7% overall humidity.

|

IZMIR, Turkey, 26 October 2001

|

This breakthrough will make a complete food

enriched with Spirulina available to the

major food aid organizations of the world.

With the countries which are members of the Intergovernmental Spirulina Program asking for it, we should be seeing improvement

in child health and less and

less malnutrition

occuring in developing countries

So, Spirulina is a wonderful

microorganism

capable of being transformed

into a complete

food when mixed with cereals.

It has been

used to treat malnutrition victims

with success

in many countries: India, Senegal,

Togo,

Vietnam, Burkina Faso, Benin,

Central African

Repubic,Democratic Republic of

Congo, Brazil,

Cuba, China, ThaIland - to name

a few. More

than a thousand scientific articles

about

Spirulina have been published;

there are

20 or more books and more than

20 doctoral

theses devoted to Spirulina.

|

WEBMASTER Site'' http://Spirulina.online.fr

'' mailto:''Webmaster'' (Updated: November

2005)

|