Harvesting by filtration | Harvesting is done by passing the culture

over a fine filter screen - polyester cloth

with 30-micron diameter holes. The filter

screen is inclined slightly so that the accumulating

Spirulina filter cake moves gradually toward

the lower edge of the filter screen, where

it is rinsed, collected, and then sent to

a dewatering station where water is extracted

by vacuum, by pressing, or by gravity through

a vibrating screen. The filter cake, or paste,

now can be cut with a knife and it will retain

its shape; but it still contains 70 to 80%

water .

| |

If the Spirulina is left in this state, because

it is such a good food it will be invaded

by bacteria and fermented into an unapproachable

stinking mass within a few hours - depending

upon the temperature. This is why the Aztecs

and the Kanembous poured the Spirulina concentrate

into shallow basins they hollowed out of

the sand. The sand allowed the water to filter

down through to the ground and the hot sunshine

dried it in 4 or 5 hours, which stopped any

fermenting action by bacteria.

However, exposure to direct sunlight bleaches

and destroys the green pigment, chlorophyll,

and degrades the B-vitamin content of Spirulina.

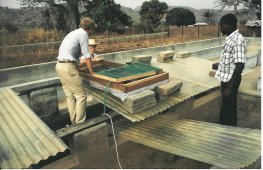

So, artisanal and small-scale Spirulina farms

use solar dryers which avoid direct contact

between the algae and the sunlight - a black-painted

metal box which allows air to pass over and

under the algae cake. |

drying spirulina on the

sand | |

Extruding Spirulina Cake | This is done by extruding fine (about 2-mm

diameter) "noodles" of the algae

cake onto plastic screens (about l-mm diameter

holes) ...screens which are stretched tightly

over wood or metallic frames that are nested

inside the dryer box ...the dryer box having

equal sized inlet and outlet holes to allow

an unobstructed passage of air .

One can improve efficiency by heating the

air under glass or plastic before it enters

the dryer box. This creates a draft which

pulls a greater quantity of air through the

box. Bear in mind that it is not the heat

that dries the algae but the capacity of

a lot of air to absorb moisture as it passes

across the algae cake.

| |

| When producing several kilograms of dried

algae per day it is much more convenient

to create a black plastic walk-in sized tunnel

equipped with a large diameter evacuation

fan. Many "noodle" trays can be

stacked one over the other in wood or metal

racks. The advantages of extruding "noodles"

onto the drying screens instead of just spreading

a thin layer of algae cake on top are, first,

that air circulates around all sides of a

"noodle" and hence the cake dries

more quickly. Second, it is much easier to

remove "noodles" from a screen

than to scrape and chip away at a smooth-surfaced

dry product. Third, spreading a film of algae

cake onto a screen pushes it into the mesh

of the screen where, when it dries, it is

gripped tightly by the screen. |

Spirulina solar drier system | |

WEBMASTER Site'' http://Spirulina.online.fr

'' mailto:''Webmaster'' (Updated: November 2005)

|